The issue of wear particles in artificial joints has long been a critical concern in orthopedic medicine. As the population ages and joint replacement surgeries become increasingly common, the longevity and performance of these implants are under scrutiny. Among the various factors affecting implant durability, the generation of wear debris stands out as a primary culprit behind complications such as osteolysis, inflammation, and eventual implant failure. Researchers and manufacturers are continuously exploring innovative materials and design strategies to mitigate this persistent challenge.

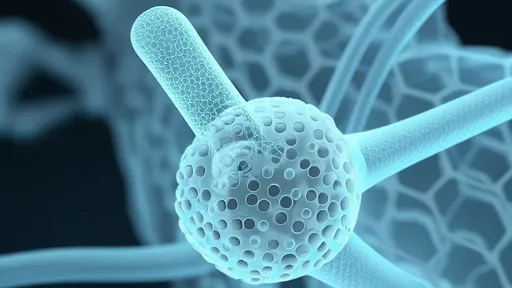

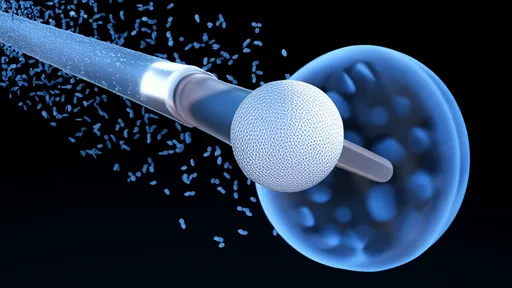

Wear particles are an inevitable byproduct of joint articulation, arising from the friction between moving components in prosthetic hips, knees, and other load-bearing implants. These microscopic fragments, often measuring just a few micrometers in size, trigger a cascade of biological reactions when they accumulate in surrounding tissues. Macrophages engulf the debris, leading to the release of pro-inflammatory cytokines that promote bone resorption. Over time, this process weakens the bone-implant interface, causing loosening and necessitating revision surgery—a costly and invasive procedure that surgeons and patients alike strive to avoid.

The composition of wear particles varies depending on the materials used in the implant. Traditional metal-on-polyethylene bearings, for instance, generate polyethylene particles that are particularly bioactive. Ceramic-on-ceramic couplings, while producing fewer particles overall, can still release nanoscale debris with uncertain long-term effects. Metal-on-metal designs, once hailed as a solution, fell out of favor due to concerns over metallosis and systemic metal ion dissemination. Each material pairing presents unique advantages and trade-offs, driving the need for a more nuanced understanding of particle-induced pathology.

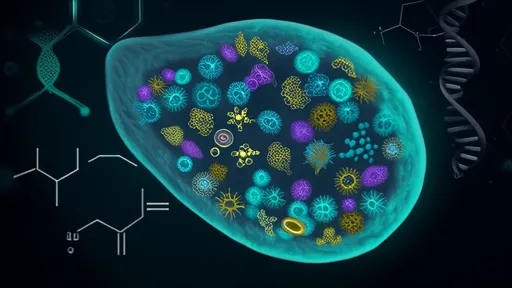

Recent advancements in material science have opened new avenues for wear reduction. Highly cross-linked polyethylene (HXLPE) has emerged as a game-changer, demonstrating significantly lower wear rates compared to conventional polyethylene. The cross-linking process alters the polymer's molecular structure, enhancing its resistance to abrasive and adhesive wear mechanisms. Meanwhile, novel surface treatments like diamond-like carbon (DLC) coatings are being investigated for their potential to create ultra-smooth, low-friction interfaces. These innovations don't merely aim to reduce particle volume—they seek to modify the very nature of the debris itself, rendering it less biologically active if and when particles do form.

Beyond materials, implant design plays an equally crucial role in wear particle management. Computer-aided design tools now enable engineers to optimize bearing surfaces with unprecedented precision, minimizing contact stresses that accelerate wear. The integration of fluid film lubrication principles—borrowed from mechanical engineering—has led to designs that maintain protective lubricant layers even under physiological loads. Some next-generation prototypes even incorporate self-healing materials or drug-eluting surfaces that could actively counteract particle-induced inflammation at its source.

The clinical implications of wear particle control extend far beyond extending implant lifespan. Reduced particle generation correlates with better preservation of periprosthetic bone stock, which becomes invaluable should revision surgery eventually be required. Younger, more active patients—who place greater mechanical demands on their implants—stand to benefit particularly from these developments. As surgical techniques improve and patient expectations rise, the orthopedic community recognizes that solving the wear particle puzzle is essential for fulfilling the promise of truly lifelong joint replacements.

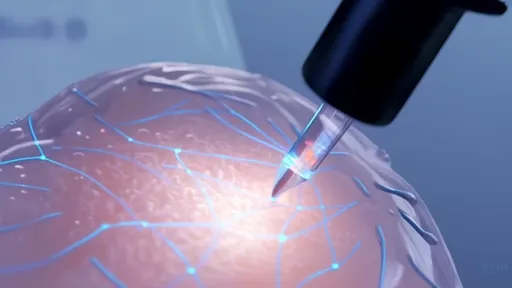

Looking ahead, the field appears poised for transformative breakthroughs. Biologic approaches, such as coatings that promote osseointegration while resisting particle migration, are moving from laboratory benches to clinical trials. Smart implants embedded with microsensors could one day provide real-time feedback on wear rates, enabling early intervention before significant damage occurs. Meanwhile, advanced imaging techniques and machine learning algorithms are improving our ability to detect and quantify wear particles in vivo, closing critical knowledge gaps about their spatial distribution and temporal evolution.

What remains unchanged is the fundamental truth that no artificial joint can perfectly replicate nature's flawless design. Yet through persistent innovation across disciplines—materials science, biomechanics, immunology, and clinical practice—researchers are steadily narrowing the gap. The control of wear particles represents not just a technical challenge, but a moral imperative to deliver safer, more durable solutions for millions awaiting the gift of pain-free mobility.

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025